Equivalent Grades of Grey Cast Iron from Different Countries |

||||||||||

| No. | China | Japan | U.S.A. | ISO | Germany | France | Russia | U.K. | ||

| GB | JIS | ASTM | UNS | DIN | W-Nr. | NF EN | гост | BS | ||

| 1 | HT100 | FC100 | GG10 | 0.6010 | EN-GJL-100 | гч10 | Grade 100 | |||

| 2 | HT150 | FC150 | 150/~No.20 | F11401 | ISO 185/JL/200 | GG15 | 0.6015 | EN-GJL-150 | гч15 | Grade 150 |

| 3 | HT200 | FC200 | 200/~No.30 | F12101 | ISO 185/JL/0 | GG20 | 0.6020 | EN-GJL-200 | гч18 гч20 гч21 | Grade 180 Grade 220 |

| 4 | HT250 | FC250 | 250/~No.35 | F12401 | ISO 185/JL/150 | GG25 | 0.6025 | EN-GJL-250 | гч24 гч25 | Grade 260 |

| 5 | HT300 | FC300 | 300/~No.45 | F13101 | ISO 185/JL/150 | GG30 | 0.6030 | EN-GJL-300 | гч30 | Grade 300 |

| 6 | HT350 | FC350 | 350/~No.50 | F13501 | ISO 185/JL/150 | GG35 | 0.6035 | EN-GJL-350 | гч35 | Grade 350 |

Gray iron is cheaper than ductile iron, but it has much lower tensile strength and ductility than ductile iron. Gray iron can not replace the carbon steel, while the ductile iron could replace the carbon steel in some situation due the high tensile strength, yield strength and elongation of ductile iron.

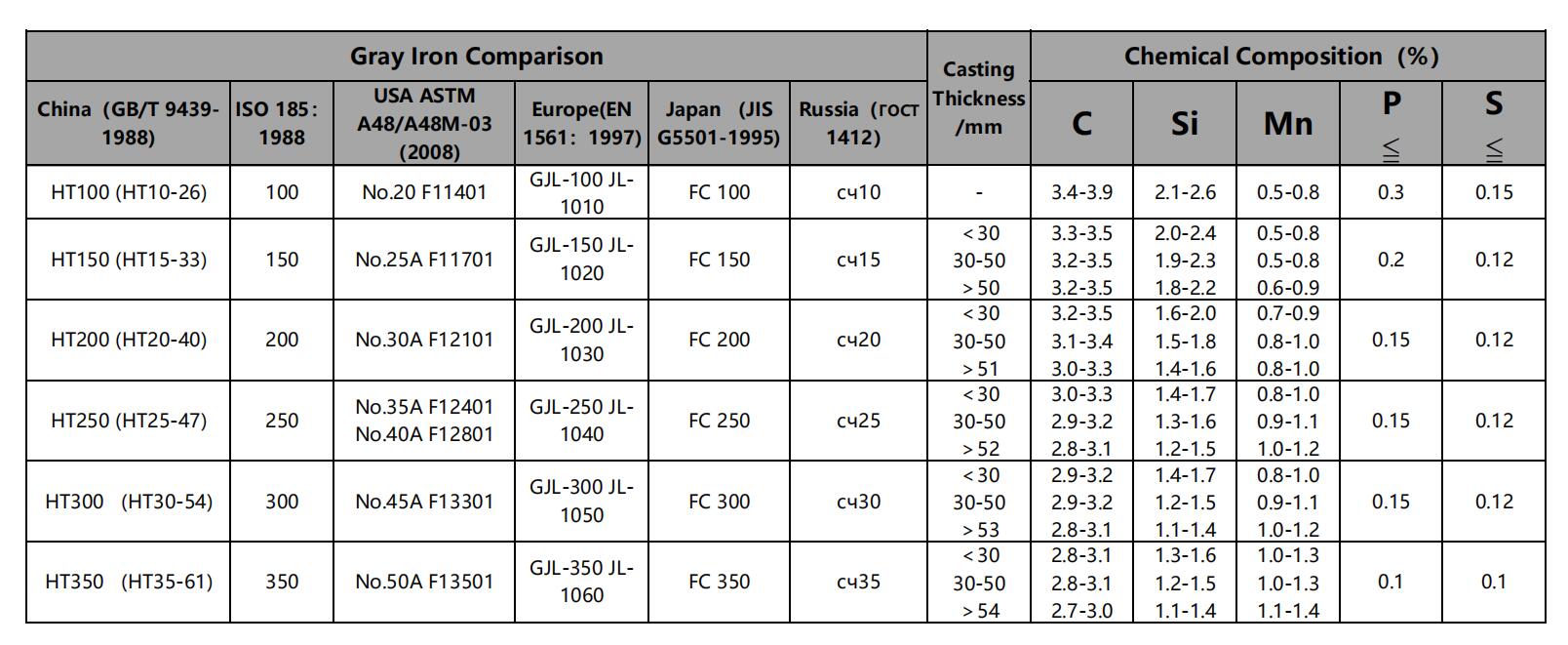

Gray Iron Chemical Composition

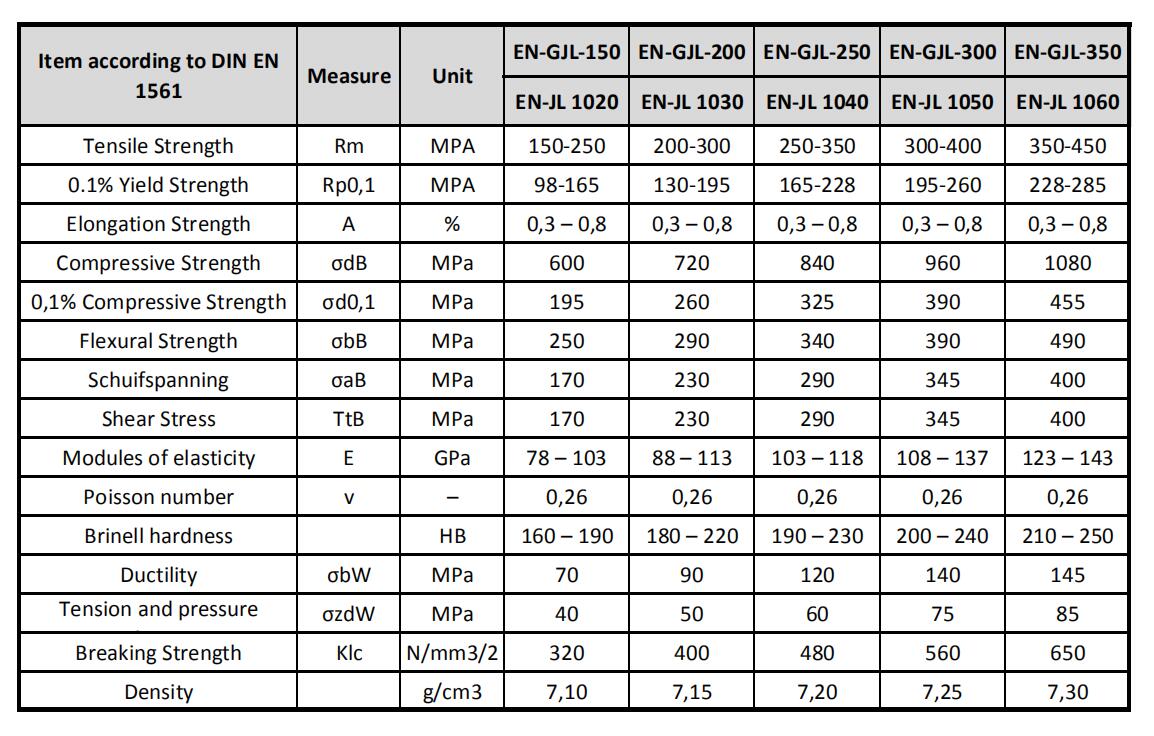

Mechanical Properties of Gray Cast Iron

A typical chemical composition to obtain a graphitic microstructure is 2.5 to 4.0% carbon and 1 to 3% silicon by weight. Graphite may occupy 6 to 10% of the volume of grey iron. Silicon is important to making grey iron as opposed to white cast iron, because silicon is a graphite stabilizing element in cast iron, which means it helps the alloy produce graphite instead of iron carbides; at 3% silicon almost no carbon is held in chemical combination with the iron.

The graphite takes on the shape of a three-dimensional flake. In two dimensions, as a polished surface will appear under a microscope, the graphite flakes appear as fine lines. The tips of the flakes act as preexisting notches; therefore, it is brittle. The presence of graphite flakes makes the Grey Iron easily machinable as they tend to crack easily across the graphite flakes. Grey iron also has very good damping capacity and hence it is mostly used as the base for machine tool mountings.

русский

русский