What We Do

Our Business

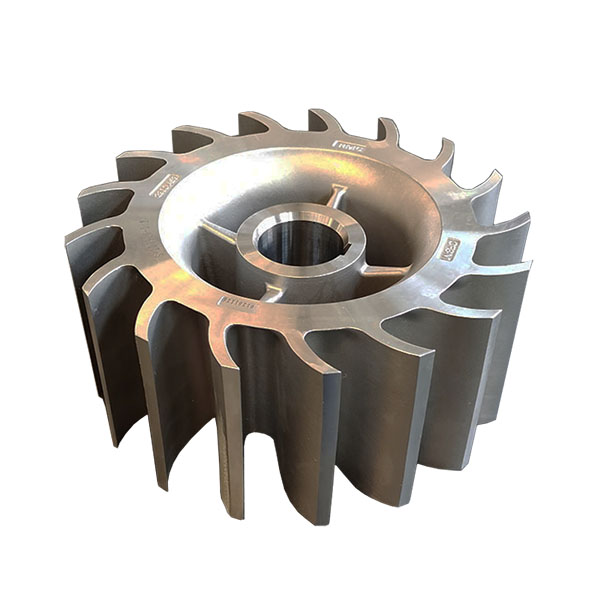

Investment Casting

Sand Casting

Shell Mould Casting

Lost Foam Casting

Vacuum Casting

CNC Machining

Our Products

Typical Products

Why Choose Us

Our Advantages

-

Rich-experienced in Sand Casting, Investment Casting and CNC Machining

RMC Foundry has its own workshop for sand casting, investment casting and CNC machining, who are serving customers in different mechanical industries across oversea markets.

-

Professional Design and Engineering

The free professional proposals on the appropriate casting / manufacturing processes, materials and a cost-down advice could be provided even before we quote.

-

One-Stop Industrial Solutions

RMC Foundry could provide the whole processes from mold design, samples, trial production, mass manufacturing, quality control, logistics, heat treatment, surface treatment and metal fabrication and after services.

-

Full Quality Assurance

From chemical composition, mechanical properties, microstructure to geometry dimensions, the real results should be 100% reach the required numbers.

-

Diverse Ferrous and Non-Ferrous Metals for Casting

We could pour grey iron, ductile iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminium, brass, bronze, nickel based alloy, cobalt based alloy...etc.

Request a Quote

Ask the Engineering Experts

RMC Foundry is ready to answer your any technical question or commercial request about sand casting, investment casting and CNC machining of ferrous and non-ferrous metals.

Just feel free to leave your message or send email to our engineering team. They will give you the professional proposals and answers based on your requirements to reach a cost-effective solutions.

Friendly Link: Metal Foundry

русский

русский