Metal Sand Casting Foundry

In RMC's foundry, we utilize the professional equipment to assemble the automatic sand casting production lines. We have two production lines for sand casting, the vertical automatic sand casting line and the horizontal automatic sand casting line. These highly organized equipment help us to produce the sand castings part of high quality and big volume. These equipment can cast a diverse materials such as grey iron casting, ductile iron casting, carbon steel, alloy steel, stainless steel, aluminium and brass.

Tooling Workshop

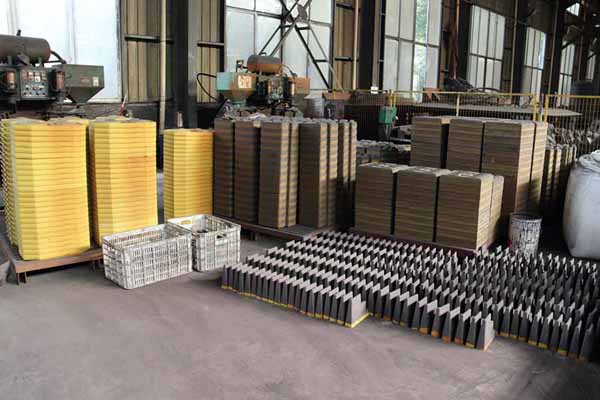

Sand Casting Toolings

Patterns for Sand Casting

Automatic Moulding Machine

Molten Metal Pouring

Shot Blasting Machine

Automatic Cleaning Line

Finished Sand Castings

Sand Casting of Grey Iron, Ductile Iron, Carbon Steel, Alloy Steel & Stainless Steel

Sand casting, which uses the sand (green clay sand, dry sand or resin coated sand) for form the casting mould for pouring molten metal, is one of the most popular and simplest types of casting. Sand casting allows for smaller batches than permanent mold casting at a very reasonable cost. Due to its well-suited for complex geometries, sand casting process takes advantage of compact sand, refractory and recyclability to produce relatively less expensive molds with quick tooling development and design changes at acompetitive cost.

There are several sand casting process based on different kinds of sand used for moulding. At RMC sand casting foundry, we proceed the sand casting process by green clay sand casting, resin pre-coated sand casting (shell mold casting) and furan resin sand casting (no bake mold casting). The pre-coated resin sand casting is also called shell molding casting or shell casting, which has much better surface for the finished castings than green sand castings.

Capacities and Molten Metal for Sand Castings

In our high tech facilities, we offer both automatic sand molding machine and manual molding operations in our resin sand casting processes. As an iron and steel foundry, RMC can pour iron castings using our no-bake casting process up to 1 ton finished weight in gray iron castings and ductile iron castings, and up to 0.5 tons in steel castings and stainless steel castings. RMC can produce casting parts in a wide variety of materials, including grey iron, ductile iron, stainless steel, carbon steel, alloy steel based on different standards from China and overseas. RMC is dedicated to the quality of our work, and our commitment to excellence ensures the highest customer satisfaction. As a global leader in high precision, high complexity, and mission critical casting and machined metal parts, we strive to meet and exceed the needs of our customers.

▶Ferrous and Non-Ferrous Metals for Sand Casting at RMC's Foundry

- Gray Cast Iron: EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, GJL-300, GJL-350

- Ductile Cast Iron: EN-GJS-400-18, EN-GJS-40-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN-GJS-800-2

- Cast Aluminium and Their Alloys

- Cast Alloy Steel, Cast Carbon Steel or other materials and standards on request

- Brass, Bronze and other Copper Base Alloys

- Stainless Steel, Nickel Base Alloys, Cobalt Base Alloys

▶ Capabilities of Sand Casting moulded by Manual (for small batches):

- Max Size of Casting Molds: 1,500 mm × 1000 mm × 500 mm

- Weight Range of Sand Castings: 0.5 kg - 500 kg

- Annual Capacity of Sand Castings: 5,000 tons - 6,000 tons

- Casting Tolerances: On Request or According to ISO 8062

▶ Capabilities of Sand Casting by Automatic Molding Machines (for big batches):

- Max Size of Casting Molds: 1,000 mm × 800 mm × 500 mm

- Weight Range of Sand Castings: 0.5 kg - 500 kg

- Annual Capacity of Sand Castings: 8,000 tons - 10,000 tons

- Casting Tolerances: On Request or According to ISO 8062

Sand Casting Inspection Capabilities

Our Spectrometer checks 15 chemical elements and metallurgical microscope produces high-resolution images 1,000 times magnified, and our cleanliness meter determines particle size and quantity to ensure materials meet or exceed the international standard. RMC use ultrasonic detectors to discover flaws, and have X-ray machines and accelerators that can scan castings with 200 mm maximum wall thickness.

RMC has a full range of inspection capabilities in house, which include:

Advantages of Sand Casting

✔ Lower Cost due to its cheap and recyclable mold materials and simple production equipment.

✔ Wide range of unit weight from 0.10 kg to 500 kgs or even bigger.

✔ Various Structure from simple type to complex type.

✔ Suitable for production requirements of various quantity

✔ Diverse metals could be cast by sand casting including ferrous metals and non-ferrous metals

✔ Long lifespan of the mold

Applications of Sand Castings

Sand casting parts could serve in many industries including hydraulics, automotive, commercial truck, rail trains, logistics, agricultural machinery...etc. The castings mainly are used as gearbox housing, pressure pump housing, engine blocks, cylinder heads, transmission box, bracket, wheel hub, connecting rods, manifolds...etc.

Our services are varied and extensive. We offer material advisory service and development, as well as advice from our technical experts on design and casting with under the help of the software of 3D and CAD drawings and simulations software. From start to finish, we have you covered every step of the way.

- Sand Casting: Green Sand Casting with Handle and Automatic Molding Machine, Pre-Coated Shell Molding Casting, CNC Precision Machining and Metal Fabrications.

- Heat treatment: Quenching, Tempering, Normalizing, Annealing, Carburization, Nitration

- Surface treatment: Anodizing, Zinc-plating, Polising, GeoMet, Zintek, Electrophoresis....etc

- Testing Service: Chemical Composition, Mechanical Properties, Fluorescent or Magnetic Penetration Inspections (FPI, MPI), X-rays, Ultrasonic Testing, Dynamic and Static Balancing Testing

RMC offers a full range of sand casting solutions. If you would like to know more about our technology and sand casting process capabilities, contact us today.

Grey Cast Iron Products

Grey Iron Casting Wheels

Grey Iron Sand Castings

Gray Iron Casting Parts

FAQs About Sand Casting

• 2D drawings with dimension tolerances and/or 3D models which we can use for calculating the unit weight easily

• Material specification including heat treatment and required mechanical properties (if needed)

• Quality assurance expectations

• Special finishing/surface treatment requirements

• Tooling if required or existing

• Due date of quote response

• Application of the part you are asking

Before we make recommendations for the project and provide you with an offer, RMC firstly analyzes the following information to make our decision and proposals based on the request information you sent:

• Tooling requirements – best suited to scope of your project

• Quality expectations required to support your technical specifications

• Machining requirements

• Heat treatments

• Finishing requirements

• Expected date of delivery

Each alloy serves a difference purpose based on issues as diverse as heat exposure, run time, weight requirements, flexibility of the end product and so on. We work with you to determine exactly how your component need to perform and then guide you to the best alloy whether you need: Cast Iron, Cast Aluminum, Gray Iron, Cast Copper Alloy, Ductile Iron, Gray Iron, Cast Steel, Zinc Alloys, Stainless Steel and any other possible metal and their alloys.

Casting is one of the fastest and most cost effective methods for producing a wide range of components. However, to achieve maximum benefits, you’ll want to involve the cost analysis at an early stage of the product design and development. We have the expertise and experience to consult with you during the design phase so our engineers can help resolve issues affecting tooling and production methods, while identifying the various trade offs that could affect overall costs.

We have different casting types for your choice. Part of the optional process for your project will be the selection of the casting process. The most popular form is sand casting which involves making a replica of a finished piece (or pattern) that is compressed with sand and binder additives to shape the final part. The pattern is removed after the mold or impression has been formed, and the metal is introduced through a runner system to fill the cavity. The sand and the metal are separated and then the casting cleaned and finished for shipment to the customer.

Moreover, we also have the shell molding process produce the iron castings and steel castings. The shell molding is usually use resin coated sand for making molds.

Lead times with sand casting, investment casting, forging and machining vary due to part complexity and casting plant capacity. Generally 4-6 weeks is typical for tooling and sample castings and 5-7 weeks for production. Once a pattern is created, a component can be produced in seven days. For investment casting processes, much of this time is spent with the coating and drying of the ceramic slurry. While for sand casting, the time is mainly cost for the mold making. Investment casting facilities in RMC have quick drying capabilities for ceramic molds to produce parts in 24-48 hours. In addition, by using silica sol or water glass as bond material, engineered cast metal components can be delivered only several days after accepting a final CAD/PDF drawings or 3D models.

Yes, we could provide the 3.1 material certificate if you request.

Typically, we can achieve the tolerance grade as per the requirements for sand casting according to ISO 8063. This would vary depending on the size and complexity of the part. Post-casting procedures, such as straightening or coining, often allow for tighter tolerances to be maintained on several specific dimensions.By working with our engineering staff, an investment casting drawing can be produced for a part that substantially reduces or completely eliminates the previous machining requirements to produce an acceptable component.

русский

русский