Stainless Steel Investment Castings

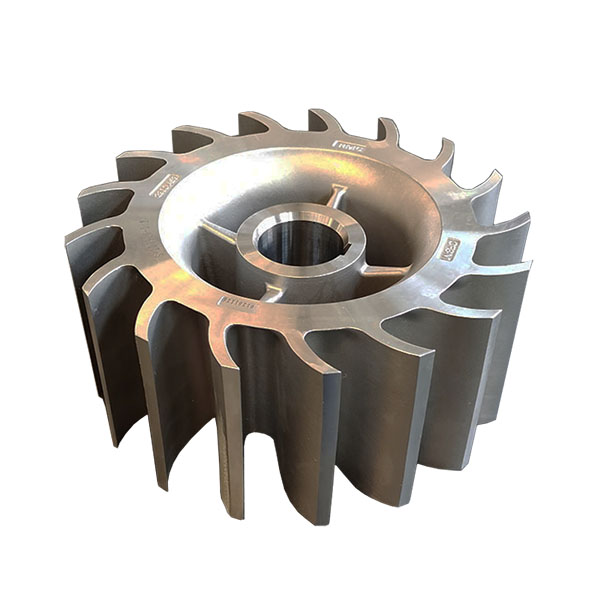

Material: Stainless Steel CF8M (1.4408) Process: Investment Casting + CNC Machining Weight: 15.10 kg Application: Open Impeller for Centrifugal Pump Heat Treatment: Solid Solution

Stainless steel investment castings with CNC machining services in China lost wax investment casting foundry. Open impeller for centrifugal pump with static and dynamic balancing.

Stainless steel investment castings from China foundry

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. It is highly corrosion resistant and wear resistant, provides excellent machinability, and is well-known for its aesthetic appearance. Stainless steel investment castings are "corrosion-resistant" when used in liquid environments and vapors below 1200°F (650°C) and "heat-resistant" when used above this temperature. The base alloy elements of any nickel-base or stainless steel investment casting are chromium, nickel, and molybdenum (or "moly"). These three components will determine the casting's grain structure and mechanical properties and will be instrumental in the casting's ability to combat heat, wear, and corrosion.

Commonly, the stainless steel should be cast by the investment precision casting process with the silica sol as the bond. The stainless steel silica sol castings have a very high grade of precision surface and performance.

Due to its unique physical properties, stainless steel castings are popular in a wide range of applications, especially those in harsh environments. Common markets for stainless steel investment castings include oil and gas, fluid power, transportation, hydraulic systems, food industry, hardware and locks, agriculture...etc.

Investment Casting Material at RMC Foundry

Martensitic Stainless Steel

100 Series: ZG1Cr13, ZG2Cr13 and more

Ferritic stainless steel

200 Series: ZG1Cr17, ZG1Cr19Mo2 and more

Austenitic stainless steel

300 Series: 304, 304L, CF3, CF3M, CF8M, CF8, 1.4304, 1.4401...etc.

Duplex Stainless Steel

400 Series: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770; 2205, 2507

Precipitation Hardening Stainless Steel

500 Series: 17-4PH, 15-5PH, CB7Cu-1; 1.4502

Carbon Steel

C20, C25, C30, C45; A216 WCA, A216 WCB,

Low Alloy Steel

IC 4140, IC 8620, 16MnCr5, 42CrMo4

Grey Cast Iron; Ductile Cast Iron

GG15 ~ GG35; EN-GJL-150 ~ EN-GJL-250; GGG40 ~ GGG80; EN-GJS-400 ~ EN-GJS-800

Super Alloy and Special Alloys

Heat Resistant Steel, Wear Resistant Steel, Tool Steel,

Aluminum Alloy

A355, A356, A360, A413

Copper Alloy

Brass, Bronze. C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100

RMC can meet material specification acc. to ASTM, SAE, AISI, ACI, DIN, EN, ISO, GB standards.

The investment casting is also called precision casting because it have much better surface and higher accuracy than any other casting process. Especially for the silica sol casting process, the finished castings could reach the CT3 ~ CT5 in geometrical casting tolerance and CT4 ~ CT6 in dimensional casting tolerance. For the casings produced by investment, there will be less or even no need to make the machining processes. To some extent, the investment casting could replace the rough machining process.

Investment Casting Technical Data at RMC Foundry |

|

| R & D | Software: Solidworks, CAD, Procast, Pro-e |

| Lead Time for Development and Samples: 25 to 35 days | |

| Molten Metal | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic stainless steel, Precipitation Hardening Stainless Steel, Duplex Stainless Steel |

| Carbon Steel, Alloy Steel, Tool Steel, Heat Resistant Steel, | |

| Nickle-base Alloy, Aluminium Alloy, Copper-base Alloy, Cobalt-base Alloy | |

| Metal Standard | ISO, GB, ASTM, SAE, GOST EN, DIN, JIS, BS |

| Material for Shell Building | Silica Sol (Precipitated Silica ) |

| Water Glass (Sodium Silicate) | |

| Mixtures of Silica Sol and Water Glass | |

| Technical Parameter | Piece Weight: 2 gram to 200 kilo gram |

| Max Dimension: 1,000 mm for Diameter or Length | |

| Min Wall Thickness: 1.5mm | |

| Casting Roughness: Ra 3.2-6.4, Machining Roughness: Ra 1.6 | |

| Tolerance of Casting: ISO8062; VDG P690, D1/CT5-7 | |

| Tolerance of Machining: ISO 2768-mk/IT6 | |

| Inner Core: Ceramic Core, Urea Core, Water Soluble Wax Core | |

| Heat Treatment | Normalizing, Tempering, Quenching, Annealing, Solid Solution, Carburization. |

| Surface Treatment | Polishing, Sand / Shot Blasting, Zinc Plating, Nickel Plating, Oxidation Treatment, Phosphating, Powder Painting, Geormet, Anodizing |

| Dimension Testing | CMM, Vernier Caliper, Inside Caliper. Depth Gauge, Height Gauge, Go/No go Gauge, Special Fixtures |

| Chemical Inspection | Chemical Compostion Analysis (20 chemical elements), Cleanliness Inspection, X-ray Radiographic Inspection, Carbon-Sulfur Analyser. 3.1 Material Certificate is Available |

| Physical Inspection | Dynamic Balancing, Static Blancing, Mechanical Properties (Hardness, Yield Strength, Tensile Strength), Elongation |

| Production Capacity | More than 250 tons per month, more than 3,000 tons annually. |

русский

русский