Casting Molds Warehouse

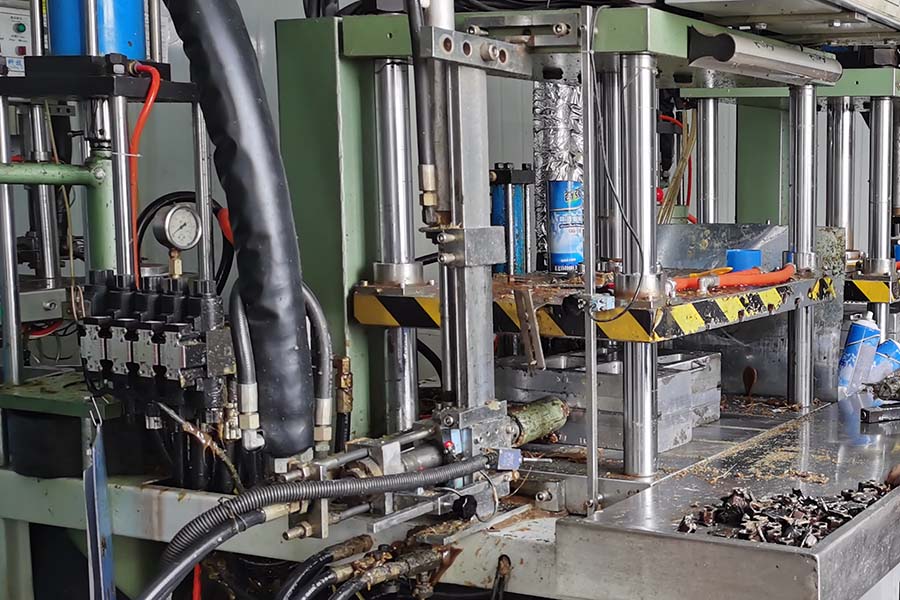

Wax Patterns Injection

Wax Patterns Injection

Wax Injection Machine

Wax Patterns

Wax Replicas

Wax Patterns

Shell Making

Shell Drying

Shell for Metal Pouring

Cooling and Solidification

Raw Casting before Cleaningg and Shot Blasting

Investment Casting Technical Data at RMC Foundry |

|

| R & D | Software: Solidworks, CAD, Procast, Pro-e |

| Lead Time for Development and Samples: 25 to 35 days | |

| Molten Metal | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic stainless steel, Precipitation Hardening Stainless Steel, Duplex Stainless Steel |

| Carbon Steel, Alloy Steel, Tool Steel, Heat Resistant Steel, | |

| Nickel Based Alloy, Aluminium Alloy, Copper Based Alloy, Cobalt Based Alloy | |

| Metal Standard | ISO, GB, ASTM, SAE, GOST, EN, DIN, JIS, BS |

| Material for Shell Building | Silica Sol (Precipitated Silica ) |

| Water Glass (Sodium Silicate) | |

| Mixtures of Silica Sol and Water Glass | |

| Technical Parameter | Piece Weight: 2 gram to 200 kilo gram |

| Max Dimension: 1,000 mm for Diameter or Length | |

| Min Wall Thickness: 1.5 mm | |

| Casting Roughness: Ra 3.2 - 6.4, Machining Roughness: Ra 1.6 | |

| Tolerance of Casting: CT5 - CT7 According to ISO 8062 | |

| Tolerance of Machining: ISO 2768-mk/IT6 | |

| Inner Core: Ceramic Core, Urea Core, Water Soluble Wax Core | |

| Heat Treatment | Normalizing, Tempering, Quenching, Annealing, Solid Solution, Carburization. |

| Surface Treatment | Polishing, Sand Basting, Shot Blasting, Zinc Plating, Nickel Plating, Oxidation Treatment, Phosphating, Powder Painting, Geormet, Anodizing |

| Dimension Testing | CMM, Vernier Caliper, Inside Caliper. Depth Gauge, Height Gauge, Go/No go Gauge, Special Fixtures |

| Chemical Inspection | Chemical Compostion Analysis (20 chemical elements), Cleanliness Inspection, X-ray Radiographic Inspection, Carbon-Sulfur Analyser. 3.1 Material Certificate is Available |

| Physical Inspection | Dynamic Balancing, Static Blancing, Mechanical Properties (Hardness, Yield Strength, Tensile Strength), Elongation |

| Production Capacity | More than 250 tons per month, more than 3,000 tons annually. |

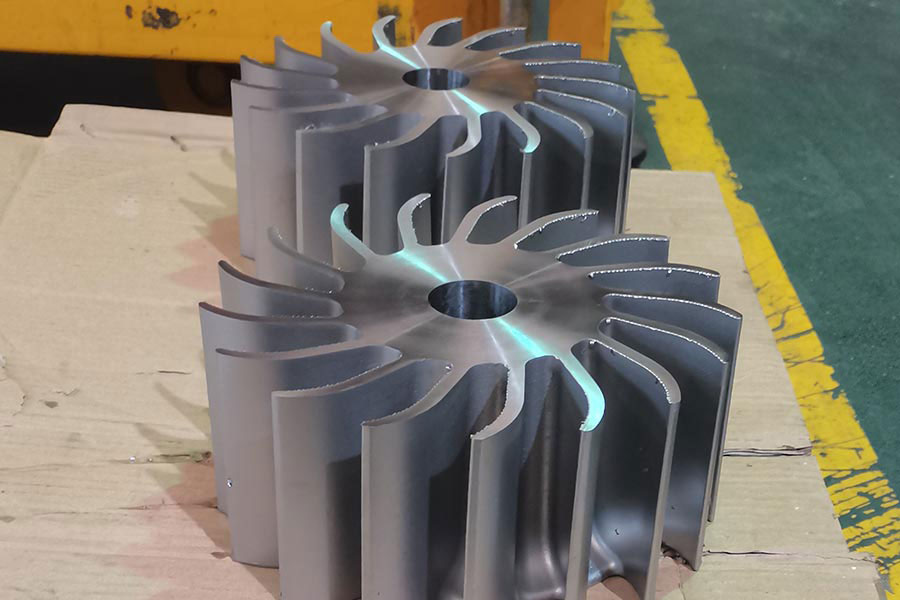

Stainless Steel Castings

Investment Castings

Stainless Steel Impellers

Stainless Steel Pump Cover

Investment Castings of Stainless Steel, Cast Steel & Cast Iron

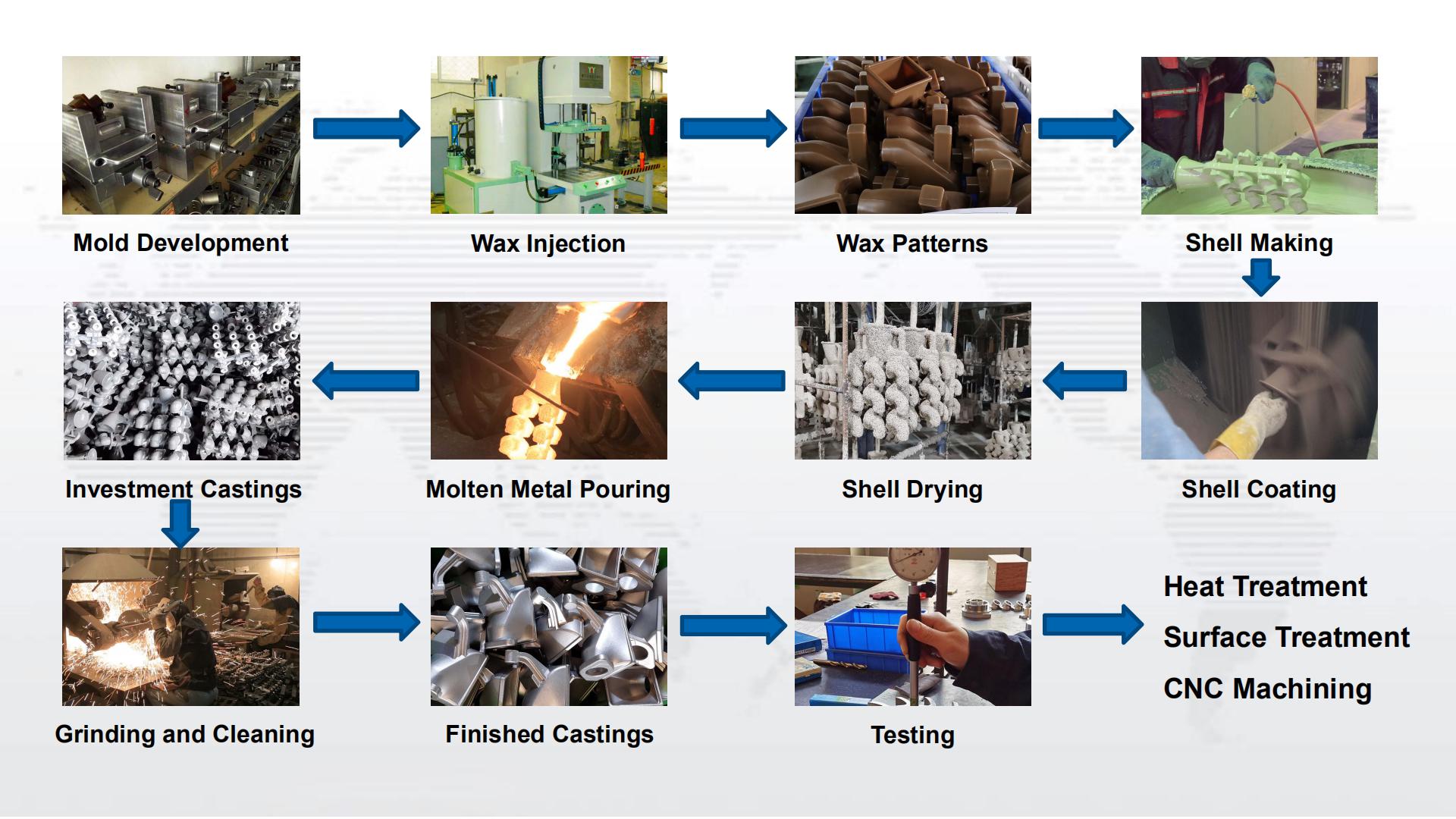

Investment casting, which is also known lost wax casting or precision casting, refers to the formation of ceramic around the wax patterns to create a multi or single part mold to receive molten metal. This process utilizes an expendable injection molded wax pattern process to achieve complex forms with exceptional surface qualities. To create a mold, a wax pattern, or cluster of patterns, is dipped into ceramic material several times to build a thick shell. De-wax process is then followed by the shell dry process. The wax-less ceramic shell is then produced. Molten metal is then poured into the ceramic shell cavities or cluster, and once solid and cooled, the ceramic shell is broken off to reveal the final cast metal object. Investment castings can achieve exceptional accuracy for both small and large castings in a wide range of materials.

Investment casting derives its name from the fact that the pattern is invested, or surrounded, with a refractory material. The wax patterns require extreme care for they are not strong enough to withstand forces encountered during the mold making. One advantage of investment casting is that the wax can be reused.

Investment Casting Capacities and Raw Materials

The metals which can be used for investment castings include low carbon steel, medium carbon steel, alloy steel, stainless steel, nickel based alloys, cobalt based alloys, aluminium alloys and other metal or their alloys. RMC's investment casting foundry is capable of meeting a wide variety of alloys material specifications according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, GOST and GB. We have more than 100 different ferrous and non-ferrous alloys with which we cast parts using complex design structure. Due to the complex structure in dimension and geometric, the investment castings are produced to net shape or near net shape, minimizing the need for secondary processes such as lathing, turning or other machining process.

Lost wax investment casting can reach dimensional tolerance grade CT 5-7 according to ISO 8062. Our fully organized equipment and automation process controls allow for consistent and repeatable tolerances as close as ±0.1 mm. The lost wax casting parts can also be produced in a wide size range, they may be as small as 10 mm long x 10 mm wide x 10 mm high and weigh as little as 0.01 kg, or as big as 1000 mm in length and weigh as much as 100 kg.

Lost wax casting processed can produce steel casting parts with good surface quality, less surface defects, high accuracy in dimensions, small but complex structure with thin wall thickness. However, the cost per unit piece of investment casting would be comparatively higher than sand casting, lost foam casting and vacuum casting processes. Generally speaking, the lost wax investment casting with water glass as shell bond is about 1.2-1.7 times of sand casting, and the lost wax casting with silica sol as shell bond is about 1.5-2.5 times of water glass castings, by weight per kilograms, depending on the structure and size of the desired casting parts.

▶ Lost Wax Investment Casting Metals

- Carbon Steel: Low Carbon Steel, Medium Carbon Steel and High Carbon Steel, AISI 1020 - AISI 1060,

- Alloy Steel: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc on request.

- Stainless Steel: CF8M, CF8, 1.4408, 1.4308, AISI 304, AISI 304L, AISI 316, AISI 316L, duplex stainless steel, super duplex stainless steel and other stainless steel gradeS.

- Nickel Base Alloys, Cobalt Base Alloys

- Brass & Copper.

- Grey Cast Iron, Ductile Cast Iron, Aluminium alloy and other Materials and Standards on request

▶ Capabilities of Investment Casting at RMC Foundry

- Max Size per Casting: 1,000 mm × 800 mm × 500 mm

- Weight Range: 0.01 kg - 100 kg

- Annual Capacity: 2,000 tons

- Binder Materials: Silica Sol, Water Glass or their mixtures

- Casting Tolerances: CT4 ~ CT8 or On Request according to ISO 8062.

▶ Advantages of Investment Casting (Lost Wax Process)

- Excellent and smooth surface finish of raw castings

- Tight dimensional and geometrical tolerances

- Complex and intricate shapes with high design flexibility and casting feasibility

- Capability to cast thin-walled castings therefore a lighter casting part

- Wide range of cast metals and alloys (ferrous, non-ferrous)

- No draft is required in the molds design

- Less or no need for CNC machining

- Less machining allowance than other casting processes

RMC Foundry is a leading precision casting factory in China of top-quality investment castings committed to delivering excellent quality, superior value and exceptional customer experience. RMC has the experience, technical expertise and quality assurance processes to consistently and reliably deliver an extensive range of precision castings with further processing.

Applications of Precision Investment Castings

Components made by investment casting are utilized to cast a wide variety of items, including high quality, high performance industrial parts of complex structures.

The application of the precision investment casting (lost wax casting process) components covers a wide range of industries, in our foundry they are typically used in the following areas (including but not limited to):

• Rail Trains

• Heavy Duty Trucks

• Automotive

• Construction Equipment

• Logistics Equipment

• Agricultural Equipment

• Hydraulics

• Valve & Pumps

Why You Choose RMC for Investment Castings

There are several reasons to choose RMC's foundry as your source for investment castings, including:

- Engineering team whose members are focusing on metal casting field.

- Extensive experience with investment castings of complex geometries

- A broad range of materials, including ferrous and non-ferrous alloys

- In-house CNC machining capabilities

- One-stop solutions for investment castings and secondary process

- Consistent quality guaranteed and continuous improvement.

- Teamwork including toolmakers, engineers, foundryman, machinist and production technicians.

RMC's foundry has more than 20 years of experience in precision investment casting. Request a quote today on investment castings for your precision parts, or contact us for more information.

FAQs About Investment Casting

Investment casting, which is also known lost wax casting or precision casting, refers to the formation of ceramic around the wax patterns to create a multi or single part mold to receive molten metal. This process utilizes an expendable injection molded wax pattern process to achieve complex forms with exceptional surface qualities. To create a mold, a wax pattern, or cluster of patterns, is dipped into ceramic material several times to build a thick shell. De-wax process is then followed by the shell dry process. The wax-less ceramic shell is then produced. Molten metal is then poured into the ceramic shell cavities or cluster, and once solid and cooled, the ceramic shell is broken off to reveal the final cast metal object. Precision investment castings can achieve exceptional accuracy for both small and large casting parts in a wide range of materials.

During the investment casting process, a wax pattern is coated with a ceramic material, which, when hardened, adopts the internal geometry of the desired casting. In most cases, multiple parts are cast together for high efficiency by attaching individual wax patterns to a central wax stick called a sprue. The wax is melted out of the pattern – which is why it is also known as the lost wax process – and molten metal is poured into the cavity. When the metal solidifies, the ceramic mold is shaken off, leaving the near net shape of the desired casting, followed by finishing, testing and packaging.

Investment castings are widely used in pumps and valves, automobile, trucks, hydraulics, forklift trucks and many other industries. Because of their exceptional casting tolerance and exellent finish, the lost wax castings are used more and more. Especially, the stainless steel investment castings play a vital important role in the shipbuilding and boats because they have strong anti-rust performance.

According to the different binder materials used for making the shell, the investment casting could be divided into silica sol casting and water glass casting. The silica sol investment casting process have better Dimensional Casting Tolerances (DCT) and Geometrical Casting Tolerances (GCT) than water glass process. However, even by same casting process, the Tolerance Grade will be different from each cast alloy due to their various castability. Our foundry would like to talk with you if you have special request on the required tolerances. Here in the following are the general tolerances grade we could reach both by silica sol casting and water glass casting processes separately:

✔ DCT Grade by Silica Sol Lost Wax Casting: DCTG4 ~ DCTG6

✔ DCT Grade by Water Glass Lost Wax Casting: DCTG5 ~ DCTG9

✔ GCT Grade by Silica Sol Lost Wax Casting: GCTG3 ~ GCTG5

✔ GCT Grade by Water Glass Lost Wax Casting: GCTG3 ~ GCTG5.

Almost most of the ferrous and nonferrous metal and alloys could be cast by investment casting process. But, at our lost wax casting foundry, we mainly cast the carbon steel, alloy steel, stainless steel, super duplex stainless steel, gray cast iron, ductile cast iron, aluminium alloys and brass. Additionally, certain applications require the use of specialized other alloys used primarily in harsh environments. These alloys, such as Titanium and Vanadium, meet the additional demands that might not be achieved with standard Aluminum alloys. For example, Titanium alloys often are used to produce turbine blades and vanes for aerospace engines. Cobalt-base and Nickel-base alloys (with a variety of secondary elements added to achieve specific strength-strength, corrosion-strength and temperature-resistant properties), are additional types of cast metals.

Yes, we could provide the 3.1 material certificate if you request.

The investment casting is also called precision casting because it have much better surface and higher accuracy than any other casting process. Especially for the silica sol casting process, the finished castings could reach the CT3 ~ CT5 in geometrical casting tolerance and CT4 ~ CT6 in dimensional casting tolerance. For the casings produced by investment, there will be less or even no need to make the machining processes. To some extent, the investment casting could replace the rough machining process.

The investment casting gets its name because the patterns (wax replicas) is invested with the surrounded refractory materials during casting process. The "invested" here means being surrounded. The wax replicas should be invested (surrounded) by the refractory mateials to withstand the high temperature of the flowing molten metals during casting.

русский

русский