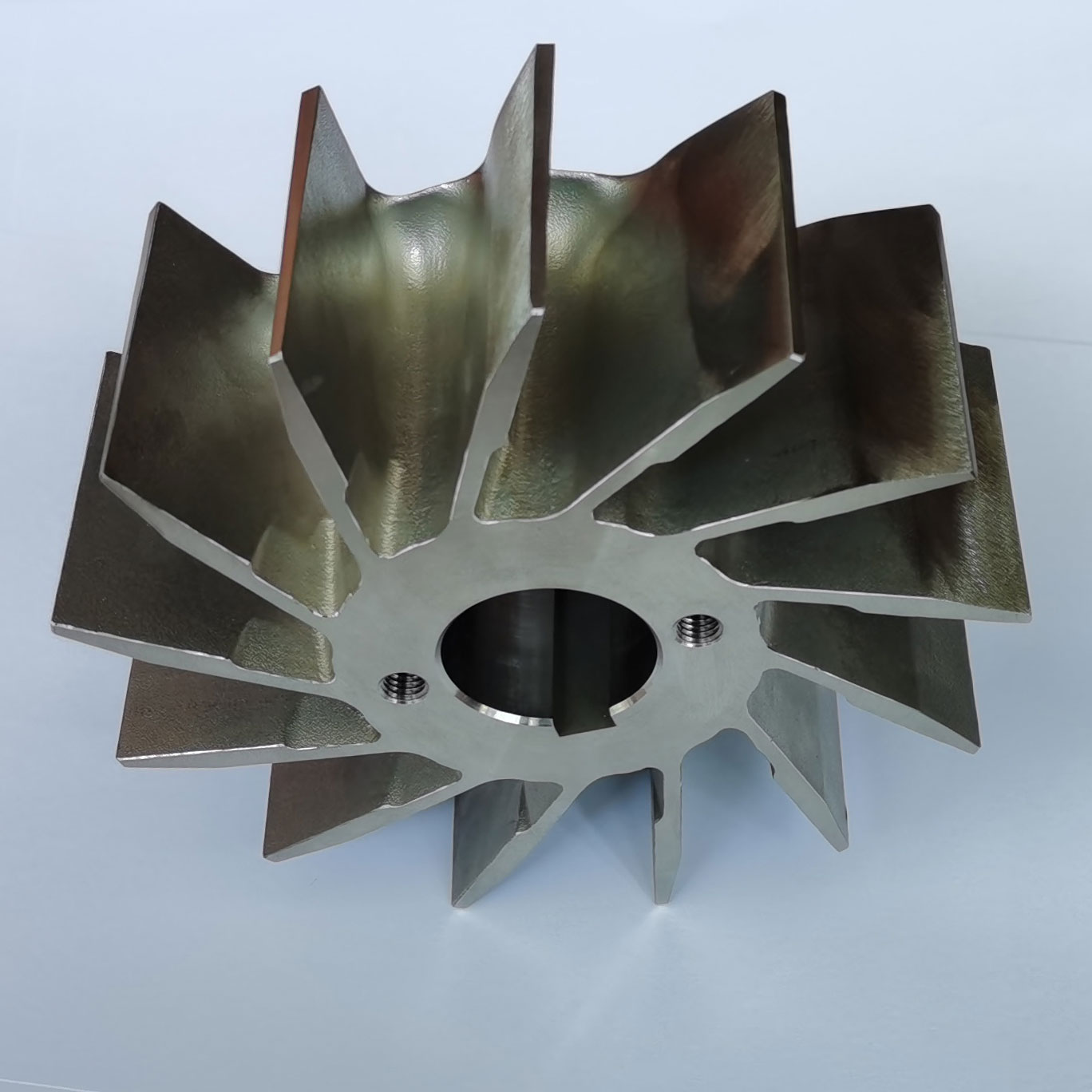

CF8M Cast Stainless Steel Open Impeller

Material: CF8M Cast Stainless Steel Process: Lost Wax Investment Casting + CNC Machining Weight: 3.50 kg Test: Dynamic Balancing

CF8M Cast Stainless Steel Open Impeller for Centrifugal Pumps

CF8M Cast Stainless Steel Open Impeller for Centrifugal Pumps

Why They Are Called CF8M?

According to the designation, the first letter C means the service it is intended to be used in corrosion resistant service , but sometimes it means of CASTING usage because you will find F 316 in ASTM A 350 ( F = FORGE). The second letter F indicates the approximate location of the alloy on the iron-chromium-nickel (FeCrNi) ternary diagram. For users familiar with the diagram, the second letter does provide an indication of the nominal iron, nickel, and chromium content, but most people would have to obtain alloying information from a material specification. The third and fourth letters 8M represent the maximum permitted carbon content in units of 0.01% (e.g., CF8M has a maximum of 0.08% carbon)

CF8M is a cast austenitic stainless steel which covered by ASTM A351, ASTM A743 and ASTM A744 standard. CF8M equal to SS 316/F 316 and Chinese Standard 0Cr17Ni12Mo2. CF8M is a molybdenum bearing modification of CF8 alloy and is the cast equivalent of wrought AISI 316 Stainless steel. The presence of molybdenum increases the general corrosion resistance and the resistance to pitting by chlorides. The alloy is used in mildly acidic and alkaline conditions and for handling citric, oxalic and phosphoric acids. Stainless steel CF8M is mostly the same as SS 316, F 316 and TP 316. But they are defined in different standards, and their chemical and mechancial properties are a little different too. CF8M is defined in ASMT A351, ASMT A743 and ASTM A744, which is for casting purpose only. SS 316 is defined in ASTM A240 and ASTM A276, it's for plate, sheet, strip or stainless steel bars. Another grade is named as F316, which is from ASTM A182 for forged parts only. TP316 will be found in ATSTM A376 for pipe only. The main applications of CF8M cast stainless steel cover: impellors, propellers, pump casings, valve bodies and press plates. The usual heat treatment for CF8M is solid Solution by heating to more than 1900 °F (1040 °C), holding for sufficient time and then quenching in water or rapid cool by other means.

Chemical Composition of CF8M Cast Stainless Steel:

Carbon: 0.08 max

Manganese: 1.50 max

Silicon: 1.50 max

Sulfur: 0.040 max

Phosphorus: 0.040 max

Chromium: 18.0-21.0

Nickel: 9.0-12.0

Molybdenum: 2.0-3.0

Mechanical Properties of CF8M Cast Stainless Steel:

Tensile Strength: min 70 ksi (485 Mpa)

Yield Strength: min 30 ksi (205 Mpa)

Elongation in 2 inch. or 50 mm: min 30.0%

русский

русский