Ductile Cast Iron CNC Machining Part

Material: Ductile Iron GGG80, EN-GJS-800-2 Process: Casting + CNC Machining Weight: 6.20 kg Application: Shock Absorber of Railroad Trains

Casting and CNC machining cast iron services from China

China ductile iron CNC machining parts by casting

CNC machining refers to the machining process proceed by Computerized Numberical Control (CNC for short). It is aided by the CNC to reach a high and steady accuracy with less labor cost. Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. The processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing, in distinction from processes of controlled material addition, which are known as additive manufacturing.

Exactly what the “controlled” part of the definition implies can vary, but it almost always implies the use of machine tools (in addition to just power tools and hand tools). This is a process used to manufacture many metal products, but it can also be used on materials such as wood, plastic, ceramic, and composites. The CNC machining covers many different processes such as milling, turning, lathing, drilling, honing, grinding...etc.

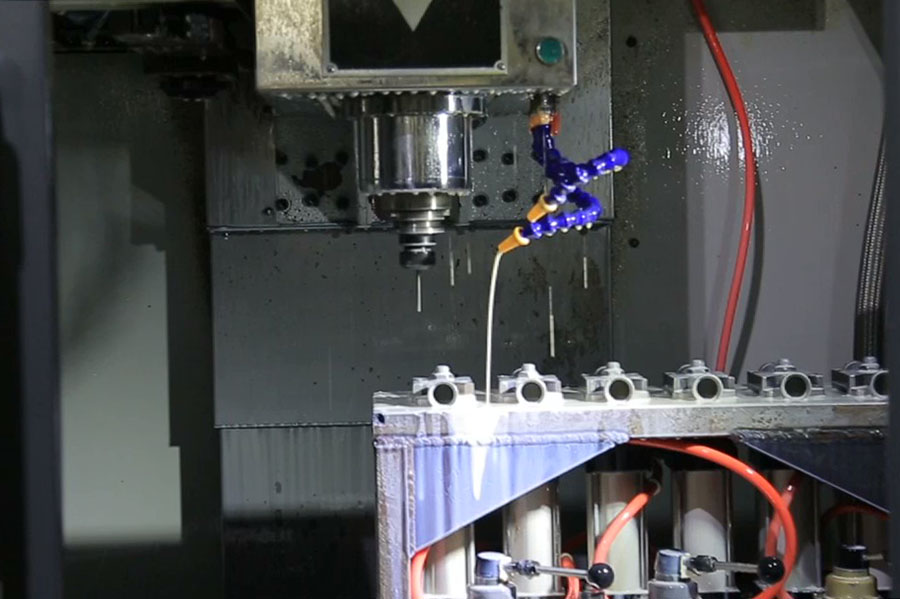

The machining center is developed from the CNC milling machine. The biggest difference from the CNC milling machine is that the machining center has the ability to automatically exchange machining tools. By installing tools for different purposes on the tool magazine, the machining tools on the spindle can be changed by the automatic tool changer in one clamping to realize multiple machining features.

The CNC machining center is a high-efficiency automated machine tool that is composed of mechanical equipment and a CNC system and is suitable for processing complex parts. The CNC machining center is currently one of the most widely used CNC machine tools in the world with strong comprehensive processing ability. It can complete more processing content after the workpiece is clamped at one time. The processing accuracy is high. For batch workpieces with medium processing difficulty, its efficiency is 5-10 times that of ordinary equipment, especially it can complete Many processings that cannot be completed by ordinary equipment are more suitable for single-piece processing with more complex shapes and high precision requirements or for small and medium batch production of multiple varieties. It concentrates the functions of milling, boring, drilling, tapping and cutting threads on one device, so that it has a variety of technological means.

Machining centers are classified into horizontal and vertical machining centers according to their spatial position during spindle machining. Classified according to process use: boring and milling machining center, compound machining center. According to the special classification of functions, there are: single workbench, double workbench and multi-workbench machining center. Machining centers with single-axis, dual-axis, three-axis, four-axis, five-axis and interchangeable headstocks, etc.

русский

русский