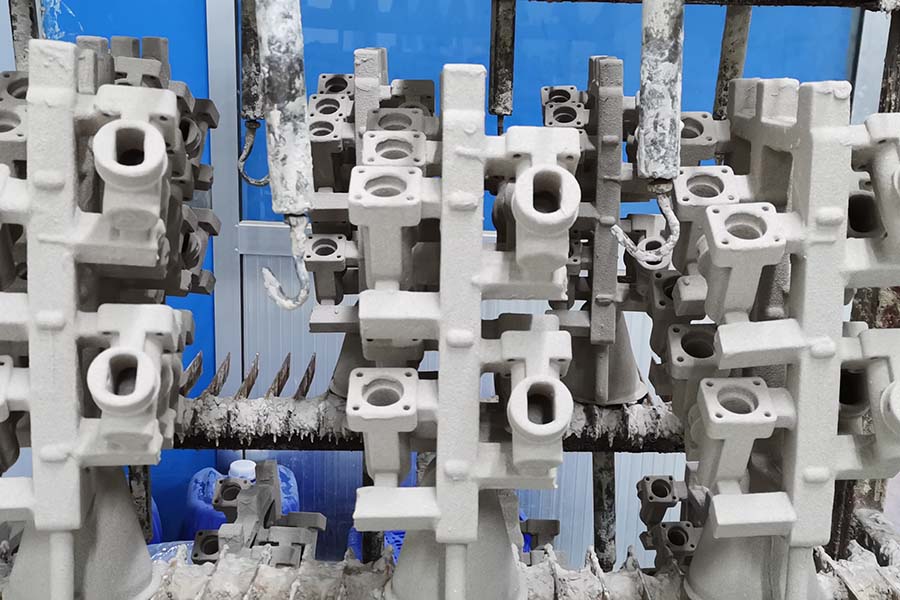

Precision Casting Stainless Steel Parts

Material: AISI 304 Stainless Steel Process: Investment Casting + Machining Weight: 1.25 kg Application: Camlock

The lost wax casting process produces near-net-shape precision metal parts that often require little or no additional machining. The resulting finish is also much better than what is achievable through other processes.

Stainless steel precision casting camlock with lost wax casting

The choice of solution temperature depends on the chemical composition and phase diagram of the cast steel. The temperature of austenitic manganese steel castings is generally 1000 ℃ - 1100 ℃; the temperature of austenitic chromium-nickel stainless steel castings is generally 1000℃-1250℃.

The heat treatment of steel castings is based on the Fe-Fe3C phase diagram to control the microstructure of the steel castings to achieve the required performance. Heat treatment is one of the important processes in the production of steel castings. The quality and effect of heat treatment are directly related to the final performance of steel castings.

▶ Raw Materials Available for Investment Casting (Lost Wax Casting Process)

• Carbon Steel: AISI 1020 - AISI 1060,• Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

▶ Capabilities of Investment Casting

• Max Size: 1,000 mm × 800 mm × 500 mm• Weight Range: 0.5 kg - 100 kg

• Annual Capacity: 2,000 tons

• Tolerances: On Request.

▶ Post-Casting Process

• Deburring & Cleaning• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Andonizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec.

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding.

▶ Why You Choose RMC for Custom Lost Wax Casting Parts?

• Full solution from one single supplier ranging customized pattern design to finished castings and secondary process including machining, heat treatment and surface treatment.• Costdown proposals from our professional engineers based on your unique requirement.

• Short leadtime for prototype, trial casting and any possible technical improvement.

• Bonded Materials: Silica Col, Water Glass and their mixtures.

• Manufacturing flexibility for small orders to mass orders.

• Strong outsourcing manufacturing capabilities.

The dimensional tolerance level of investment castings can reach CT4 ~ CT7. Among them, the dimensional tolerance grades of cast steel investment castings, cast iron investment castings, nickel-based alloy investment castings and cobalt-based alloy investment castings are generally CT5 ~ CT7. The dimensional tolerance level of light metal and copper alloy investment castings can reach CT4 ~ CT6.

русский

русский