Stainless Steel Casting Foundry

Material: Stainless Steel Process: Investment Casting, Lost Wax Casting, CNC Machining Weight: 1.92 kg Casting Tolerance: CT4 - CT6

The investment casting gets its name because the patterns (wax replicas) is invested with the surrounded refractory materials during casting process.

Stainless Steel Casting Foundry with CNC Services

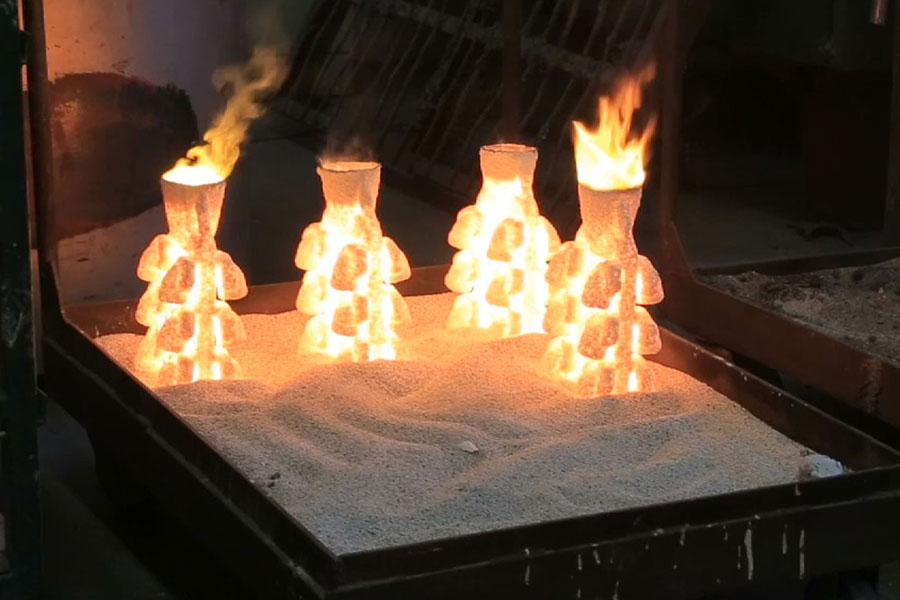

Every casting produced by the lost wax casting starts as a disposable wax duplicate (thus the term "lost wax") that is injection molded in a permanent die built with allowances for the process. Wax shrinkage, refractory shrinkage and alloy shrinkage are all factors considered when cutting the die cavity. Very complex shapes can be achieved by incorporating the use of soluble wax cores and/or preformed ceramic cores or a combination of both into the wax part. Each wax part is then assembled with the runner or sprue system, also called gating, to form what is commonly called a "tree", "case" or "setup". A tree can consists of one wax part, or in some cases, hundreds of wax parts.

▶ Raw Materials Available for Investment Casting (Lost Wax Casting Process)

• Carbon Steel: AISI 1020 - AISI 1060,• Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

▶ Capabilities of Investment Casting

• Max Size: 1,000 mm × 800 mm × 500 mm• Weight Range: 0.5 kg - 100 kg

• Annual Capacity: 2,000 tons

• Tolerances: On Request.

The castings obtained by the silica sol shell making process has low surface roughness, high dimensional accuracy and long shell making cycle. This process is widely used in casting high-temperature heat-resistant alloys, heat-resistant steels, stainless steels, carbon steels, low alloys, aluminum alloys and copper alloys.

In the investment casting process, the water glass binder and coating have stable performance, low price, short shell-making cycle and convenient application. The water glass shell making process is suitable for the production of investment castings such as carbon steel, low-alloy steel, cast iron, copper and aluminum alloys that require less surface quality.

русский

русский